- English

- 한국어

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Español

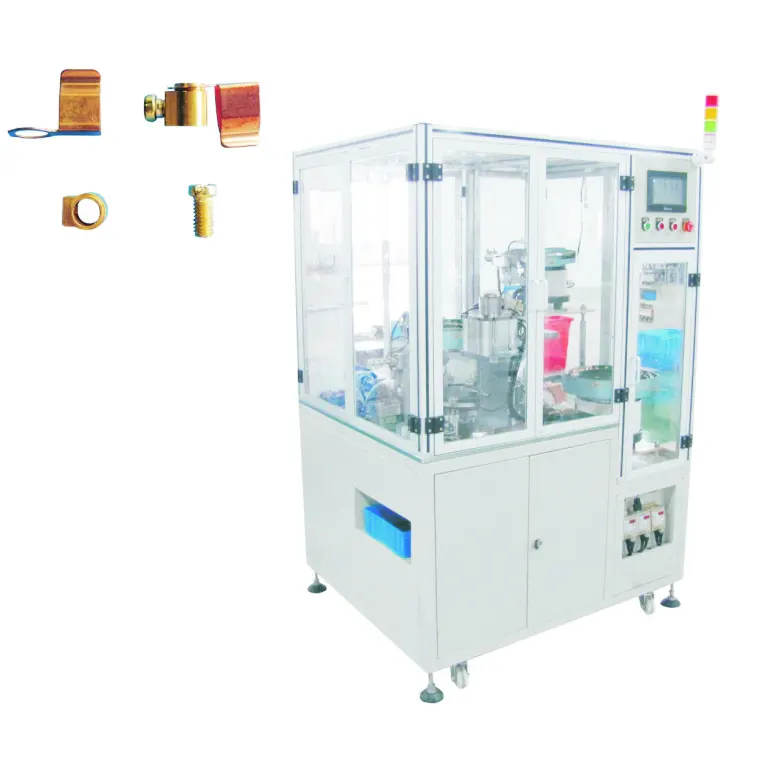

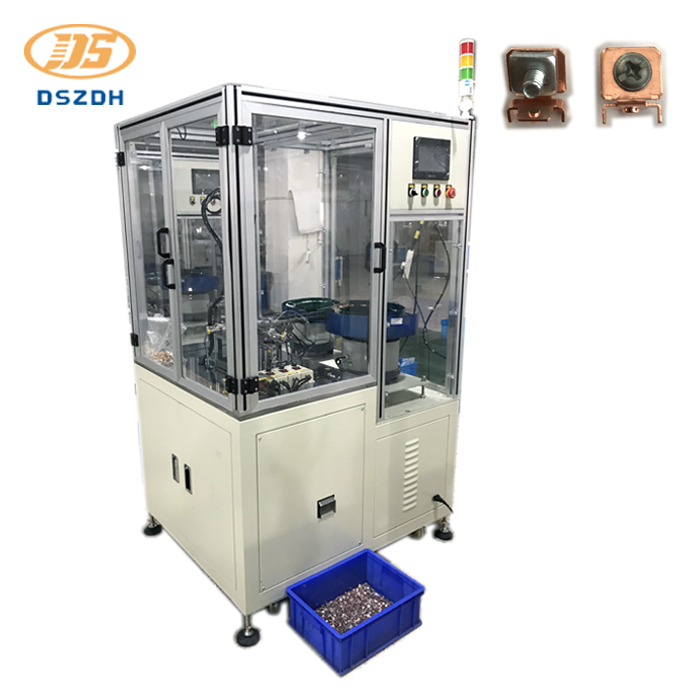

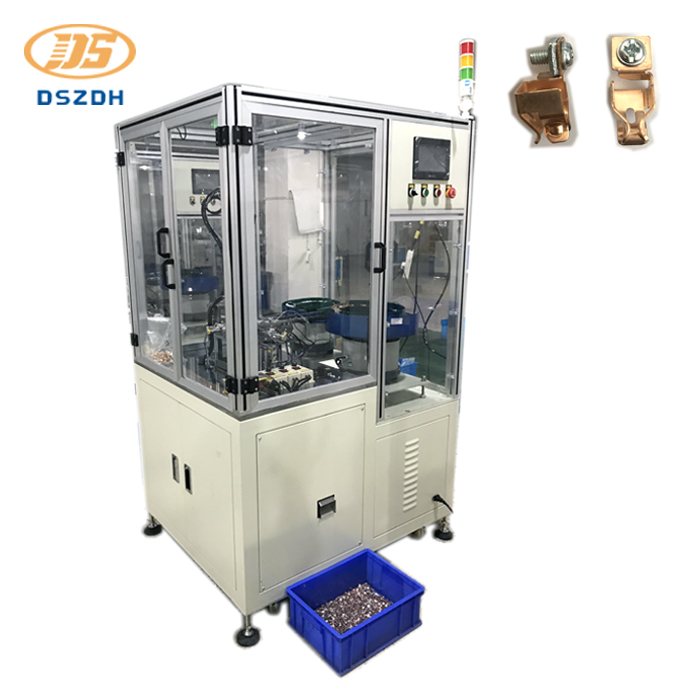

Automatic Screw Fixing Machine

Desheng is a professional manufacturer of Automatic Screw Fixing Machine. Our professional expertise in manufacturing Automations has been honed over the past 12+ years. This Automatic Screw Fixing Machine is specially designed and manufactured for switchgear and electrical and electronic components industry. Automatic mechanical production replace manual operation. We are a high-tech factory devoted ourselves to automation industry for 12+ years. We are striving to provide excellent automation solutions and outstanding service for global customers.

Model:DS

Send Inquiry

Product Description

This Automatic Screw Fixing Machine canreplace manual operation and realize mechanical production of locking screws. This machine has automatic detection function and automatic alarm stop function. And it can automatic counting and you can set the output on the touch screen, it is intuitive interface, simple and safe.

Desheng Automation was founded in 2008, we are a high-tech manufacturer specialized in providing best customized automation solutions for precision electronics, automotive parts, new energy, switchgear industry and robotics. We have cooperated with many famous enterprises, such as CHINT, DELIXI, Panasonic, Siemens, Marquardt, Havells, Salzer and other famous enterprises. Our products and service have won the recognition and trust of more than 500 customers.

Desheng is striving to become an expert and outstanding service provider in automation industry.

Product Parameter(Specification)of Automatic Screw Fixing Machine

|

Productivity: |

30 ~ 35 pcs / min |

|

Working pressure: |

0.5+-0.1 Mpa |

|

Power supply: |

AC 220V / 50Hz |

|

Feeding mode: |

Vibratory bowl feeders |

|

Dimensions: |

Customized |

|

Weight: |

Customized |

Product Feature and Application of Automatic Screw Fixing Machine

This Automatic Screw Fixing Machine isspecially designed and manufactured for switchgear, electrical and electronic components industry. Automatic mechanical production replace manual operation.

Product Details of Automatic Screw Fixing Machine

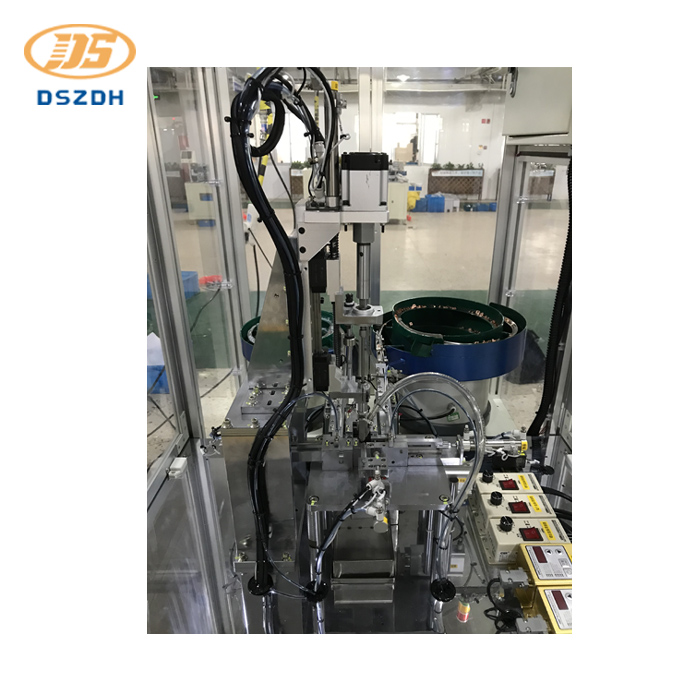

(1) PLC control systerm.

(2) Auto feeding with vibrating bowl feeders. Screws are automatically taken out and sent to the front end of the screw driver rapidly and stably, which makes up for several deficiencies of traditional method of taking out screws manually.

(3)Automatic detection, start and stop with or without material.The good product and NG product will be output separately.

(4) Automatic counting and output setting.

(5) Touch screen, intuitive interface, simple operation and safe.

(6) Automatic alarm stop in case of abnormal, and display abnormal information.

(7) The machine can greatly improve the production efficiency and reduce the cost. The working efficiency and working quality greatly exceed manual screwing.

DESHENG is a high-tech manufacturer with advanced automatic intelligent equipment manufacturing technology and independent intellectual property rights. Since 2009, DESHENG has provided many automatic intelligent equipments to switch socket appliance industry, relay industry, low-voltage appliance industry, precision electronics industry, auto parts industry and new energy industrial control products. Our products were exported to all over Asia, Europe, Africa and South America, and have won the recognition and trust of more than 500 customers. Our customers include Marquardt, Siemens, Phoenix, CHINT, DELIXI, Nader, LEEDARSON, DONGNAN, BULL, HAVELLS and other famous enterprises.

DESHENG has established manufacturing standards in cooperation with industry leaders. From design, structure, component procurement to assembly and testing, we always follow strict standards and keep improving.

Our professional team is committed to the R&D and improvement of structure, machinery, process technology and control. We work closely with you to ensure that each generation of your equipment can improve your use experience and investment return.

DESHENG is striving to become an expert and outstanding service provider in the field of automation industry.

If you want to realize automatic production of any product, please do not hesitate to contact us. We will customize and provide excellent automatic assembly machine and solutions according to your requirements. We have over 15 years of experience in the production of automatic assembly machines.

Cooperation Process

-

Evaluate and customize the proposal based on your samples, drawings, and technical requirements.

-

Customer confirm the proposal, and we provide a quotation.

-

Sign a contract

-

3 D modeling and Manufacturing

-

Delivery, training and after-sales service

CUSTOMER CASES

Exhibition

Our Clients

Certificate

FAQ

1. Where is your company located?

- Yueqing city, Zhejiang province.

Detailed address :

ZHEJIANG DESHENG INTELLIGENT EQUIPMENT TECH. CO., LTD.

No.222 Wei Wu Road, Yueqing Economic Development Zone, Yueqing City, Zhejiang Province, China. 325600

Katharina Xu, Mobile: +86-15157717628, E-mail: dszdh06@163.com

2. How much does this Automatic Wall Switch Assembly Machine cost? Please provide a quotation.

- The machine is customized, we need to evaluate your product before we can provide a quotation.

3. What information do you need to provide a quotation?

- Please provide physical samples, 2D 3D drawings, technical requirements (production capacity, appearance requirements...).

After receiving these information, we will evaluate the product and provide you the proposal within one week. After your confirmation, we will send you the quotation.

4.What is the delivery time?

- It takes 60-90 working days.

5. How many trialing materials do you need for machine testing?

- Usually we need 3000-5000 pcs components for machine testing. In order to ensure stable machine operation, we need sufficient materials to fully test the machine. After testing is completed, we will send back all materials with machine to you.

6. What is the warranty for the equipment?

- One year warranty after delivery. (Not including the spare parts)

7. How about after-sales service?

- Usually you can easily run the machine according to our instructions and video guidance. If you got any problems, you can contact us at any time, and we will remotely connect to the machine to check the problem and help you to solve it.

We have experience in overseas after-sales service, and all overseas after-sales costs need to be borne by the customer themselves.